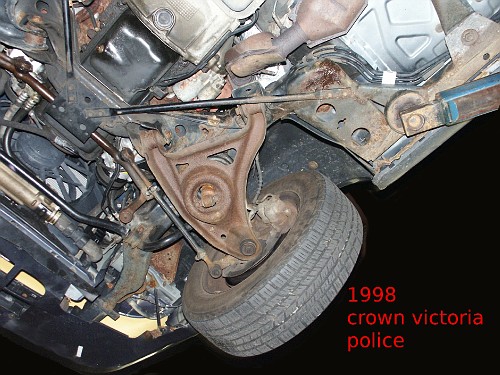

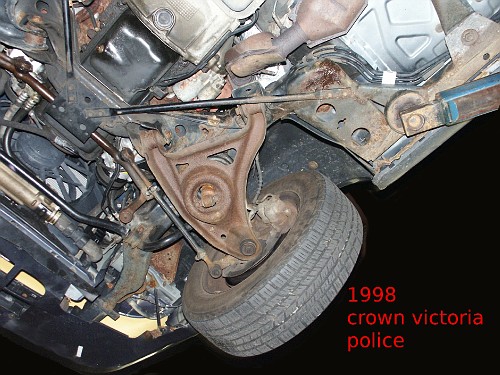

Below are some pictures of the undercarriage of a 1998 ford crown

victoria police interceptor. When these pictures were taken, the

vehicle in question was around 11 years old.

Here's the front of the car. Here you can see the suspension control

arms, oil pan, steering linkage, and oil cooler.

Here's a closeup of the oil cooler system

A few years back , the front suspension on this car was overhauled. The

control arm on the right is a ford dealer service assembly for a 1998

crownvic. The one on

the right was from a salvaged ~2 year old 20k mile 2002 crown

victoria. Sometime in the 1999 model year, ford stopped painting the

control arms and the difference in corrosion is quite visible between

the two.

Here's a closeup of the bottom of the transmission

And the catalytic converters

Here's the rear axle assembly and fuel tank. This rear suspension setup

is called a "Watt's

Linkage". 1998 was the first model year for this particular rear

suspension setup in the crownvic. And 1997 and prior cars will look

somewhat different in the rear.

Also note that at some point, the axle

appears to have been overfilled with oil resulting in significant

overflow out the differential vent tube. Interestingly, this oil is not

visible when the car is sitting on the ground under normal ambient

lighting.

Here's a closeup of the bracket which holds the tranny cooler lines to

the engine block. Also visible is part of the starter motor and a the

frame where the lower control arm mounts.

Here's are the tranny cooler lines from a different angle. Part of the

oil pan, transmission and starter are also visible.

A closeup of the new ~2 month old visteon a/c compressor. Notice how

all of the black factory paint is still present on the clutch assembly.

Here's the trunk floor. For 10 year old 100k+ mile police cruiser in

this area of the country, the trunk floor is in good condition. Do note

that the majority of the car owning general public will never see this

part of their car under these particular lighting conditions.

The black box in the middle of the trunk floor contains the evaporative

emissions charcoal canister and related valves. All 1998+ crownvics

should have this part. But in rural police departments, you'll

sometimes find this item ripped clean off the floor from offroading

adventures. Note that 1997 & prior vehicles have the charcoal

canister located in an alternate location and the floorpan in the back

won't have this part attached to it.

Most 100k+ mile police cruisers will have a little oil seepage

in between the engine oil pan and the engine block near where the

transmission meets the engine. As long as the oil doesn't

drip on the ground and you don't run your car out of oil, this doesn't

usually cause any problems.

Do pay attention to any leaks coming from the transmission bellhousing

though. If the transmission front pump->torque converter seal is

leaking, you might want to shy away from purchasing the car at auction.

Once one tranny seal starts to fail, others are often not far behind

including the clutchpack lipseals.

Many of the early 1992-1997 aero-body crownvics will have a cosmetic

plastic cover that extends from the radiator core support to the engine

crossmember. This part blocks access to numerous suspension and engine

components. For people that like to tinker with their cars, you can

remove this plastic cover and retain the bumper cover to the core

support with some nylon cable ties without any ill effects.

Notice how protected the engine oil pan is in relation to the 2003+

crownvics. Engine damage from a mangled oil pan in the pre-2003 cars is

relatively rare even in severe duty police use.

From the factory, these cars used "lubed-for-life" suspension

components that do not have an grease fittings. But all of the

suspension joints on this car have been replaced with aftermarket

components that are greaseable.

This car had a ford remanufactured transmission installed several years

ago. The remanufactured transmissions from your local ford dealership

are coated with a gloss grey paint. Most of the paint on the bottom of

the transmission has worn away, but it's still present on the top and

sides of the tranny.

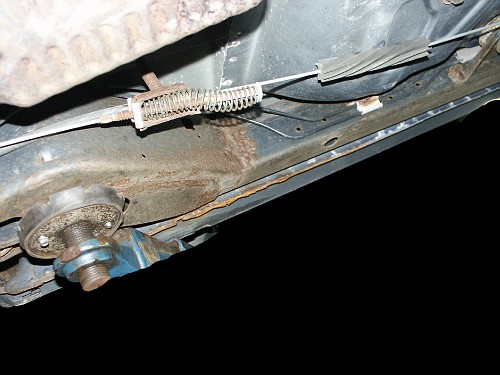

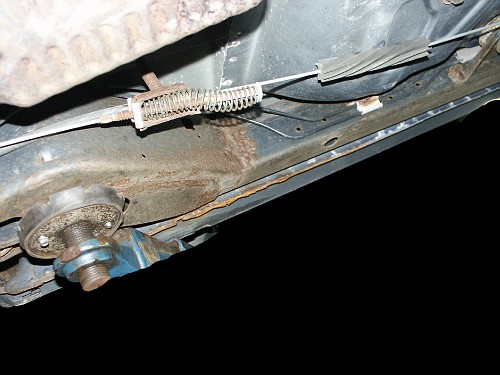

Lets take a look at the emergency brake system

Here's the front portion of the e-brake cable where it comes through

the firewall and passes through the frame

Here's how the e-brake cable passes through the firewall into the frame

Here's how the e-brake cable passes by the transmission crossmember

Here's the e-brake cable floorpan insulator and the adjustment mechanism

A closeup of the ebrake cable adjuster and floorpan insulator

The electrical cable passing through the floor near the adjuster is for

one of the rear axle wheel speed sensors for the antilock brake system.

If you remove the rear seat in your crownvic, you can see the other

side of this cable.

Here's how the e-brake cable passes over the rear axle

A closeup of how the e-brake cable is attached to the shock absorber

tower and maneuvers around the swaybar

The e-brake shoe backing plate

The other side of the car

Here's the fuel filter. All 1998+ crownvics use the same mounting

location, however the earlier aerobody crownvics had the fuel filter on

the opposite side of the car.

To remove the fuel line connections, springlock tools are required. In

theory, you simply slide the spring lock release tool into the garter

springs and the fitting releases. But this often doesn't happen in the

salt belt states due to corrosion and a salt crust layer locking parts

together. And yes, stainless steel

does corrode, it just "stains less" than a steel without a high

chromium content.

Here's a closeup of the muffler. The two small circular holes are to

drain water out of the muffler. These holes are factory installed and

are supposed to be there.

Here's the bottom of the floorpan where the front two seats mount.

A closeup of the big washers that the front seat bolts mount into.

On some cars, you'll need to hold these stationary with a pair of

pliers to stop them from spinning when you remove the bolts above. In

other cars, you'll find these big washers are missing and have been

replaced with some generic washers/nuts from the local hardware store.

Here's a closeup of the crash bracket that the seat belt latch attaches

to

Here's the rear axle assembly vent tube. This tube allows excess fluid

pressure to vent to the atmosphere but keeps water from getting in.

This part has a

habit of going missing to parts unknown. If you need one of these

molded hose assemblies for your crownvic, the part # is F5AZ-4023-AA.

Here are some pictures of the rear sway bar setup

The rear sway bar links in these cars are solid metal not a hollow tube

with a bolt passing through like you'll often find in other vehicles

Here's the top of the swaybar link where it passes through the

vehicle's frame

Do note that the routing of the evaporative emissions canister hoses

changed a little bit in later model years. Here's a picture of a 2000

crownvic trunk floor next to a 1998 one.

Notes:

-These pictures were taken with crown victoria internet discussion

forums in mind. It's sometimes really difficult to describe an issue

without good pictures of the parts in question. And taking good

pictures of undercar parts can be really difficult for the a

casual shadetree mechanic. For these pictures, tools were used that

many backyard mechanics don't have including: a high-end DSLR

camera, a commercial 2 post shop lift,

and

lots

of

overhead

lighting.

-There are some additional pictures of this car with all four

tires/wheels removed avaliable by clicking here.

-This car has a factory installed blue paint job complete with blue

colored undercar body panels. On cars that have been repainted a

different color, you'll find that the color of the trunk, doors, hood,

etc does not match the color of the body panels underneath your car.

This is convienent if you're shopping for a pre-owned crownvic and are

wondering if it's ever been repainted.

-The blue color of the undercar body panels really shows the road salt

deposits. On a white car, road salt deposits would be much more

difficult to see.

-There has been some talk about corrosion. This is a really complex

topic that you can find numerous engineering books written about. But

in an oversimplified sense, there are a few different corrosion

enviroments scattered around the united states.

--The "Rust Belt Car". The winter in these areas gets cold and lots of

rock

salt and sand are used to clear snow/ice from the roadways. The salt

greatly

accelerates the rate at which exposed metal corrodes. Lots of abrasive

debris is present during the winter from airborne ice particles and

sand. The summers in these areas are often rather humid too.

--The "Southern State Car". The winter in these areas is relatively

mild.

Road salt is not used, but the roads are sanded in some locations. Cars

in these states will get light surface rust but nothing like the heavy

scaly rust that you'll get in the salt belt. The summers in these areas

are sometimes longer and more humid than the rust belt states.

--The "Desert Car". For corrosion to take place, water is required. In

an dry arid enviroment like phoenix arizona, metal parts are unable to

rust

due to lack of water. Plastic and rubber parts often have a rather

short life in such an enviroment. Air conditioning system parts often

don't fare much better in these high heat enviroments either.

As you can see, much of the factory installed rust preventative

coatings have worn away on this car. This is typical of a car 10+ year

old car in the northeast. This is not a show car, so the main concern

with undercar part corrosion is lost functionality. For example:

Perforated brake lines or oil pans that leak fluid through holes that

aren't supposed to be there. A suspension control arm that doesn't

attach to the frame anymore because the control arm box rotted off.

etc...

Some toyota tacoma and 4runner truck owners have commented that the

rear differential axle assembly looks rusty on this car and could "rot

through" sometime soon which would cause fluid leaks. Unlike toyota

vehicles, ford uses really thick metal on the differential. So even if

a lot of metal is lost because of thick scaly rust, you've still got a

really thick peice of metal left behind to seal fluid in and bear the

rear suspension loads. On older ford vehicles, you'll sometimes

encounter rusted out spring perches or rear differential covers, but

having the axle tubes or carrier pumpkin of the axle assembly develop

rust pinholes that oil can leak out through is

unheard of (even in the salt belt states). Attempting to lower vehicle

weight and save money on production costs by purchasing less steel to

build an axle assembly was not one of toyota's better ideas.