BlueFusion

on www.crownvic.net decided to install new aftermarket polyurethane

swaybar bushings on his 2000 mercury grand marquis. This sounds like a

simple task in theory, remove two nuts, cut off the old sway bar

insulators, install the new bushings, and reassemble everything.

But on older crownvics, the frame studs often break loose and spin when

you attempt to remove the swaybar bracket nuts. Using pneumatic air

impact tools helps lower the chances of this happening, but does not

completly eliminate this problem.

One of the swaybar bracket bushings

The studs in the frame were rust-locked to the nuts and spun when the

nuts were turned. So they were cut off

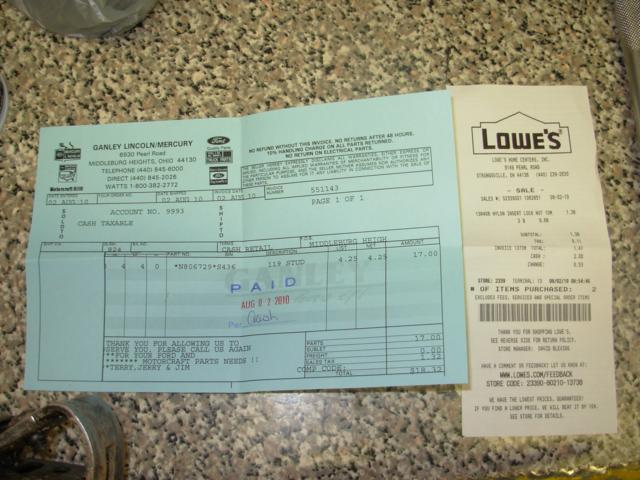

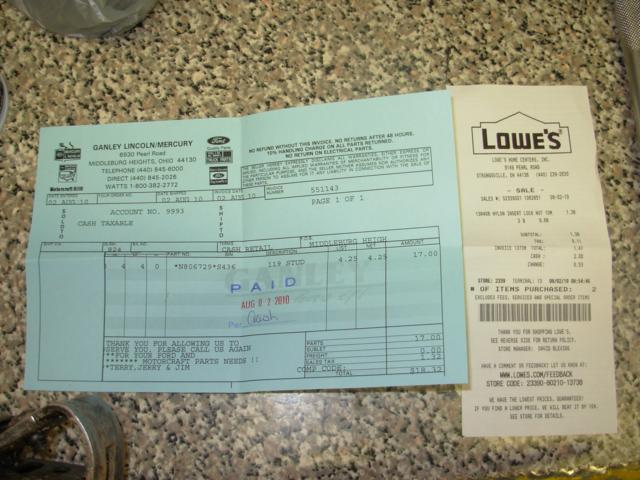

New N806729-S436 swaybar bracket retainer studs were ordered from the

local ford dealer

The nylon locking nuts were expensive at the local ford dealer, so a

couple high strength ones were purchased at lowes

The aftermarket swaybar insulators come with a slit in them so you do

not have to remove the swaybar endlinks to install the bushings. The

slit in the oe ford rubber bushings was cut for ease of removal.

Swaybar insulators are wear items. In extreme cases of wear, one end of

the swaybar bushing will turn into an elliptical "egged-out" shape.

When this happens, your car's handling characteristics will suffer. By

100,000 miles, these bushings will have had the swaybar moving up/down

millions of times.

On my own crownvic, I use replacement oe ford rubber swaybar bushings.

But some people like the stiffer poly-urethane ones instead.