EATC Interior Temperature Sensor

Since the eatc setup is supposed to be able to maintain the interior

temperature at a user defined setting, it needs a sensor to tell it what

the current interior cabin temperature is.

But since air temperature varies throughout the vehicle with

small pockets of hot and cold air dispersed throughout, to get an

accurate temperature reading one will have to sample the air by either

pushing or pulling it across the sensor. In crown vics, the interior air

temperature is sampled by a sensor with three open ports on it. The

bottom port connects to a hose from the underhood evaporator housing which

forces air through a white hose. The white hose then connects to the sensor

and forces air out the port immediatetly across from the inlet. The port

on the front then vacuuums air in through it by the venturi effect.

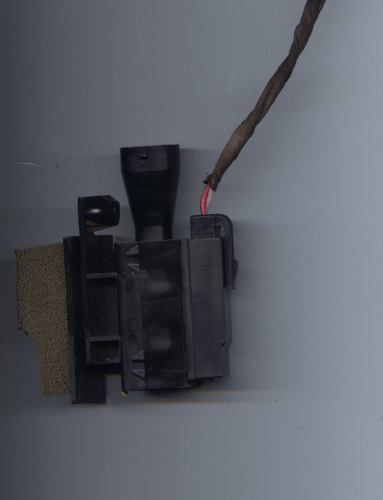

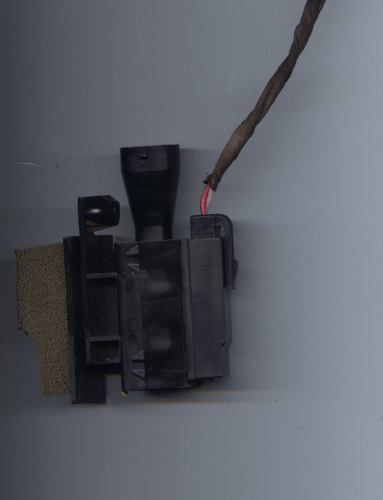

Below is a picture of the underhood evaporator housing with

it's hose attached. On the left, is the blower motor, in the middle

the evaporator, and on the right the blower motor speed controller.

When the blower motor wheel spins, it forces air through the hose. If

the hose becomes obstructed with debris such as dead insects or tree leaves,

the interior temperature readings will become inaccurate as a result.

And the other end of the hose is connected to the interior

temperature sensor.

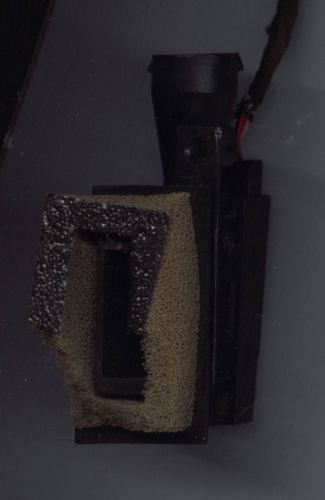

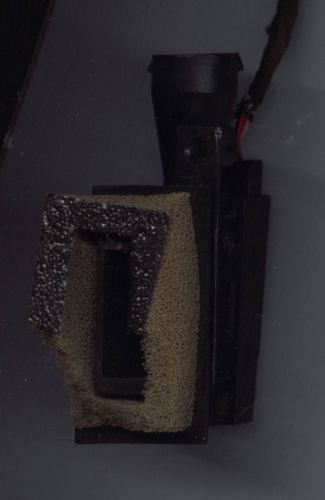

When air is forced in through the round port above, it flows

out through the rectangular port below.

In the process of moving air through the sensor, interior

air is vacuumed in through the front port over a thermistor by the venturi

effect. The thermistor converts temperature data into an electrical signal

useable by the eatc control circuitry.

Conveniently, my police interceptor's dashboard already had

the cutout in it for the interior temperature sensor.

And with a little effort, the sensor slipped into the dashboard

cutout. The dashboard trim on my police interceptor which covers the

interior temperature sensor already had the cutouts in it to allow air

to flow to the sensor as well.

The hole was also drilled in the pre-drilled in the firewall

for the hose from the underhood evaporator housing. There was insulation

covering the hole, but it was pre-stamped with a circular cutout

so I was able to pull it out with my fingers and touch the cutout for

the underhood evaporator box where the temperature hose fitting would

be.

Like the pre-cut hole in the firewall, the manual a/c evaporator

housing had the mounting location for the evaporator hose fitting

on it. After pushing out the insulation with my finger, I could now

see the blower motor wheel. Courtesy of a wrecked police cruiser with

a shattered evaporator housing, below are some pictures of the portion

of the housing in question.

I had purchased an entire evaporator housing assembly from

a wrecked eatc equipped crown vic that was involved in a rear impact,

but later decided that I was going to modify my current manual evaporator

housing instead. First step was to remove the passengers side fender

liner, next was to remove all the fasteners that held the evaporator

housing to the firewall and finally remove the hoses from the heater

core. Now I could push the evaporator housing a little bit away from the

firewall and install the needed fitting. This was easier said than done

though as I couldn't visually see the insulating foam that I was scraping

away with my finger and maneuvering a wrench to secure the 8mm fasteners

in place was very difficult.

The a/c flex hoses that connect to the evaporator did flex

and allow me push the evaporator a little bit away from the firewall.

But now i'm getting refrigerant oil residue & yellowish-green tracer

dye on the junction of the lower evaporator and the flex hose. Perhaps,

the o-rings on the quick connect fitting started to leak solely because

the car is 5 years old, but my suspicion is that jostling around the evaporator

contributed to their early demise. In retrospect, it probably would have

been easier to discharge the refrigerant from the a/c system and install

the junkyard evaporator assembly onto my car.