Below are some pictures of the front brake system in a 2000 ford crown

victoria

The front caliper pistons being compressed using a large eight inch

c-clamp

To prevent debris from the calipers from being pushed back into the

master cylinder and antilock brake valve block, the bleeder valve can

be opened some. This will also prevent the master cylinder reservoir

from having fluid flow out over the top.

Now that the caliper pistons have been retracted, the caliper can be

removed from it's bracket

Here's a closeup of the old pads. The pads still have some useable life

left in them, but are going to be replaced anyways.

During assembly at ford's manufacturing plant, the rotors are held onto

the wheel hubs using a couple lock washers or rivets. These parts are

not needed once the car has rolled off the ford dealer's showroom

floor. And if your car has ever had the rotors removed for service

before, you won't find any rivets or lock washers here.

Here is a 2000 crownvic with the rotor lock washers still installed

indicating that the rotor has never been seperated from the hub

before.

And here is a 1999 crownvic with the rotor->wheel hub rivets still

installed indicating that the rotor has never been seperated from the

hub before.

picture courtesy of vonirkinshtine on

www.crownvic.net

After drilling out the rivets and installing a new brake rotor.

picture courtesy of vonirkinshtine on

www.crownvic.net

Here's the dual piston caliper that you'll find in the 1998-2002

crownvics

Here are the new performance friction brake

pads to install

The passenger's side of the car is essentially a mirror image of the

driver's side

A closeup of the brake system on the passenger's side front of a 1998

crown victoria

Make sure that the anti-rattle clip doesn't fall out of the caliper

when you remove the pads.

Here are the rotor and pads from a 1998 crown vic

The oem rotors for this car were manufactured are stamped Varga.

Varga is currently a brazil division of the automotive supplier TRW.

A closeup of the F8VC-1125 Ford casting information

The 1992+ crownvics have sealed front wheel bearings and the rotor hat

sits on top of the wheel bearing hub. So to have a "true" rotor that

doesn't wobble when brake pads are clamped against it, not only must

rotor runout be within acceptable limits but the wheel bearing hub

surface must also be clean and not have excessive runout either.

This wheel bearing isn't too rusty for a car this age in this area of

the country. But with 100k+ miles, it's somewhat worn and is going to

be replaced while the rotor is off anyways.

The wheel hub is held onto the spindle using a single nut hidden behind

a dust cap.

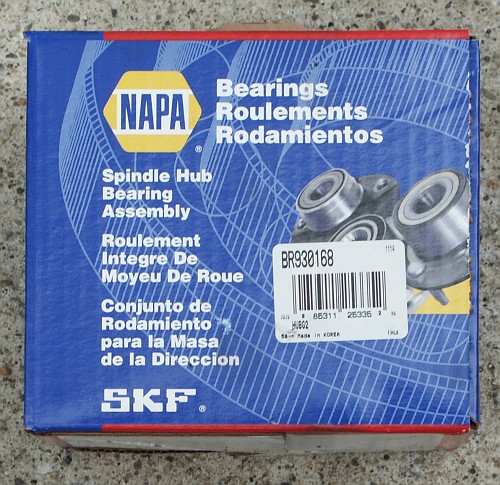

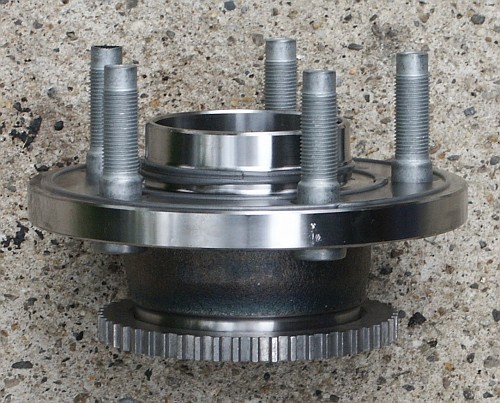

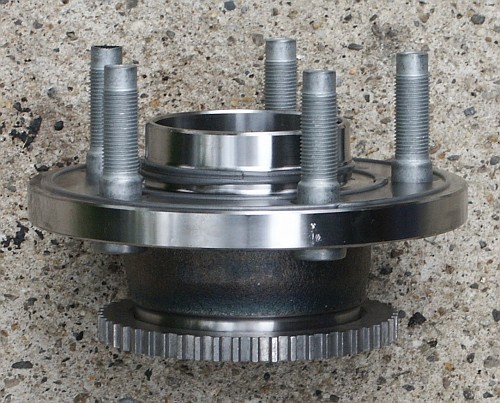

Here's the new wheel bearing hub assembly to install. No noticebale

rust present and the actual bearing of the hub assembly is much tighter

than the old one too.

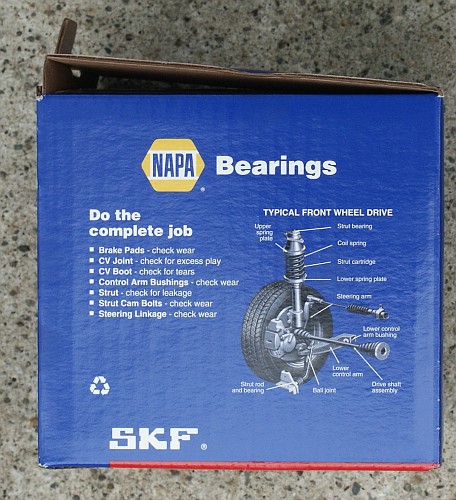

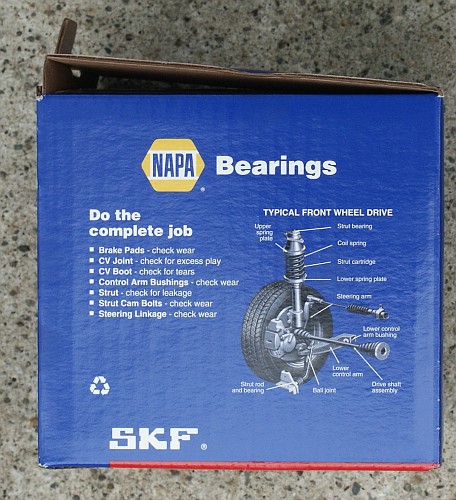

This box is generic for all of NAPA's SKF wheel bearings. Crownvics

don't have struts or cv joints.

After the protective plastic cover has been removed

The layer of antiseize compound around the outer edges of the hub is to

keep moisture out so the metal doesn't corrode and cause excessive

runout.

In the aftermarket, wheel hubs always seem to come with the antilock

brake sensor exciter ring installed regardless of whether you tell the

parts counter person that your car has antilock brakes or not. This

reduces the number of different part numbers that need to be stocked on

the store shelves.

Here's a closeup of the antilock antilock brake wheel speed sensor

setup. Metallic brake dust debris can be cleaned off the sensor using

an aerosol can of brake parts cleaner.

This picture shows the later 1998+ solid stainless steel abs exciter

ring.

1992-1997 vehicles have a stamped steel abs tone ring that sometimes

corrodes badly on "rust belt" vehicles operated in areas of the country

where large quantities of chloride salts are used on the roads to clear

snow/ice during the winter. having some teeth go missing from an abs

tone ring due to heavy scaly rust will get the abs warning light

illuminated on your cars dashboard in a hurry.

The 1995+ crown vics have removable front caliper brackets.

If for some reason you are replacing the front caliper with a new

service assembly during your brake job, make sure to remove the two

bolts which retain the caliper to the bracket prior to removing the

caliper bracket from the car. This will make sure that the caliper

bracket stays stationary while you are removing the bolts from the

slide pins.

During a brake job, make sure to lubricate the slider pins with some

dielectric grease to prevent moisture intrustion and the associated

corrosion

Many professional fleet repair shops that work on a lot of crownvics

keep a spare set of these slider pins on hand. Failure points to watch

for include:

-damage to the threads

in the end of the slider pins where the caliper bolts would normally be

located

-evidence of corrosion from water intrustion. mechanically removing

corrosion with sandpaper or a wire brush is only a temporary mickey

mouse repair that will cause

problems in the future. the proper solution for a long lasting repair

is to replace the affected caliper slide parts with new service

assemblies.

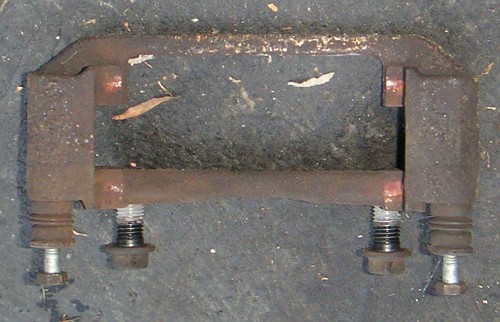

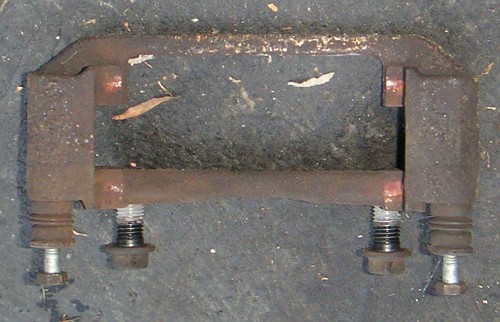

Some professional fleet repair shops also keep spare caliper brackets

on hand too.

The failure points to watch for here are:

-corrosion around where the boots seal to the bracket that could let

moisture in

-corrosion inside the bracket where the sliding pins would normally be

located

-excessive wear in the area where the pads slide on the bracket

The bolts which retain the caliper bracket to the spindle are installed

really tight and have thread locker factory installed too. A 24-inch

breaker bar with a strong 18mm impact socket usually

gets them out without too much trouble though.

You don't normally have to remove the whole steering knuckle from the

car in order to do a brake job. But some other suspension work was

being done on the car during this project. And it's easy to get good

pictures of knuckle when it's out of the car.

Here's the back of the steering knuckle. The two holes on the far left

are where the caliper bracket bolts would normally pass through.

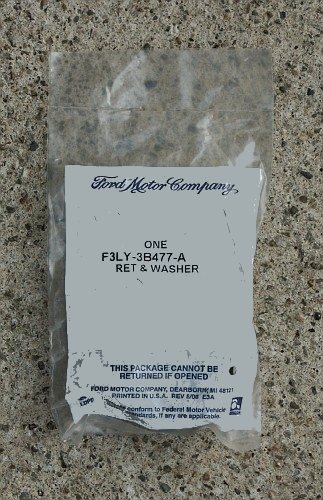

The nut which retains the wheel hub to the steering knuckle is a torque

to yield fastener that the ford shop manual states must be replaced

everytime it is removed. But many mechanics report sucessfully re-using

these nuts and not having the wheels fall off any of their customers'

cars yet.

You will want a 36mm axle nut socket for this nut.

Here is a 1997 crown victoria

Here is the same 1997 crown victoria with a 1998-2002 brake rotor

installed on it. Notice the additional surface area?

Here is a 1997 rotor next to the later 1998+ "big brake" one

If you are interested in upgrading your 1979-1997 crown victoria to the

large brake setup pictured above, then click here for

additional information about this topic.

Here is the caliper bracket from a 1997 crown victoria. This unit is

physically smaller than the 1998 unit and doesn't have the removeable

brake pad slide surface slippers either.

The bracket does use a similar sliding system to allow the front

calipers to float though.

Here is a set of 98-02 "big brake" pads next to the 1997 ones.

Below are some random front suspension pictures from a repair project

on a 1998 crown victoria. Eventually, these will be moved to a

different location. But for now, this webpage is in rough draft stage.

Notes:

-Liquid has a tutorial

online

about changing the brake pads and rotors in the 1998-2002 cars

online.

-For street driven cars, I recommend rubber flex hoses rather than the

braided stainless steel ones. With a track driven car, you probably

will never get debris wedged in between the stainless braid and the

teflon hose inside which could wear through and cause fluid leaks like

you might on a street driven car.

There is a wiki page

about this topic. Yes, this is a honda website. But SS brake flex hoses

for acura vehicles are constructed the same as the ones for ford

vehicles.

-If you can't get your rear brake rotors off the axle, do be aware that

there is a minature parking brake mechanism that may be holding you up.

There are a couple picture scrapbooks online that may assist you with

this part of the project. The first scrapbook is of a 1997 crownvic, the other

scrapbook is of a 2000

crownvic. All the 1996-2002 cars use essentially the same TRW supplied rear parking brake setup.