Below are some notes about installing a 200 amp mitsubishi alternator

from a 2009 ford crown victoria police interceptor into a 1998 crownvic

that originally came with a 135amp ford 6G alternator.

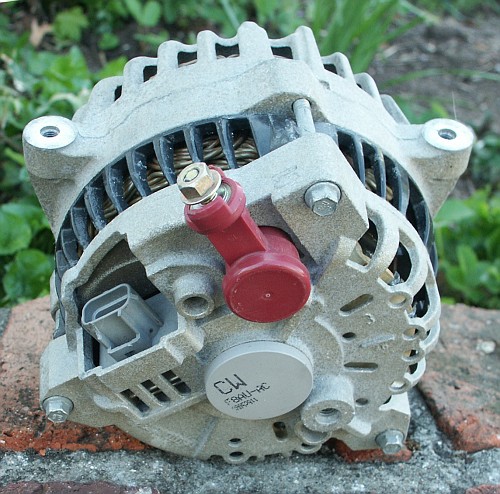

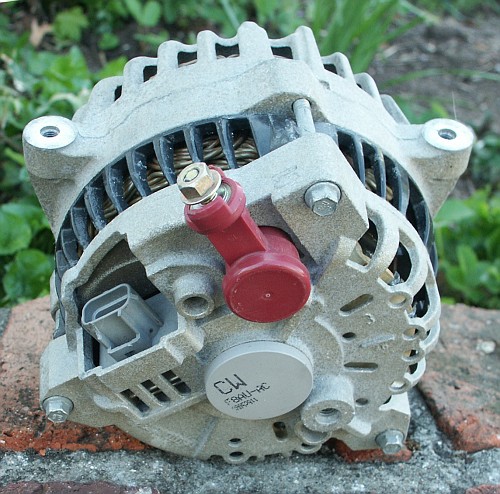

Here's the alternator we want to upgrade to.

This unit has about 10k miles on it and was in use for about a year

before the car was wrecked.

In the northeastern united states, large quantities of chloride road

salts are applied to the roads during the winter to melt

snow and ice. And this how an alternator looks after just one new

england

winter.

The pulley on this alternator is clutched due to the high rotating mass

of the alternator rotor. The one way clutch locks when rotated

clockwise, but freewheels when rotated in the other direction. When

car's engine is running, the alternator clutch will be locked most of

the time, but it will freewheel during hard acceleration when the

transmission shifts cause abrupt changes in the engine crankshaft

rotation speed. It will also freewheel when the engine is shut off and

the inertia of the heavy rotor keeps the alternator shaft spinning for

a bit. Do note that this is just a "one-way" clutch and not an "overrunning alternator

decoupler" (OAD) pulley like you'll find in some other vehicles.

There is a little surface rust on the pulley because the alternator sat

unused for several months after the car was wrecked. This came right

off after the alternator was installed in a car and run for a couple

hours with the serpentine belt rubbing against the metal.

Here is the 200 amp tag on the alternator

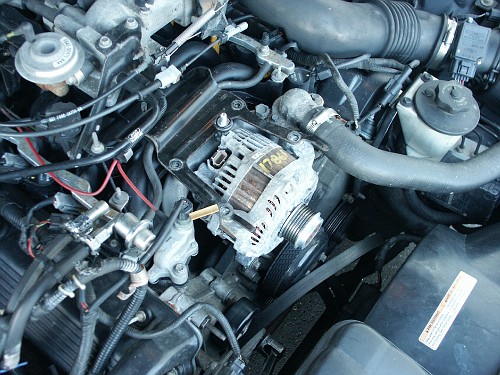

Now let's take a look at the 135amp sixth generation (6G) ford

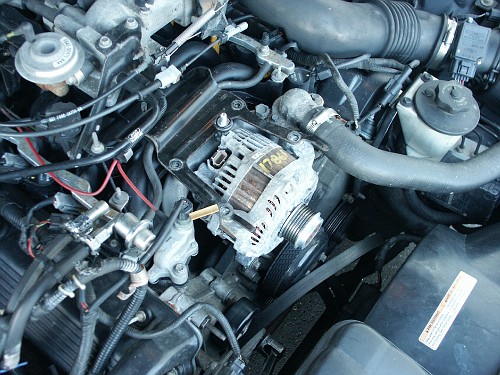

alternator in the 1998 crownvic that we want to upgrade.

After removing the front engine accessory belt from the alternator

The alternator with the high current charging wire disconnected and the

top mounting bracket removed

The alternator top support bracket from the top

The bracket from the bottom. The raised area in the bracket is to

protect the fuel rail hose during a very high energy frontal collision.

Here are the 4 mounting bolts for the alternator

After loosening the bottom two mounting bolts, unplugging the regulator

connector, and lifting the alternator out

Now that the alternator old alternator is removed, we can try to

install the "new" one.

The alternator physically fits on the engine. But, the regulator wiring

is too short to reach the regulator in it's new location due to the

different location of the regulator connectors on the two different

alternators.

Besides the physical length of the regulator wiring, there is also

another hidden issue here of this late model alternator regulator being

controlled with different electrical signals than this earlier model

car generates.

But for now, we are concentrating on the physical fitment issues of the

alternator rather than the electrical control side.

Here are the two alternators side by side. Note the different location

of the regulator connector.

Also, the opening in the ring terminal on the alternator output wire is

too small to fit over the alternator output post stud.

The serpentine belt fits over the alternator pulley without any

modification.

Also, the alternator top mounting bracket does not fit properly with

the new alternator installed. Before the alternator bracket can be slid

so that it's bolt holes line up with the alternator and intake manifold

bolt holes, bracket hits up against the output charging post. A little

work with a 4" angle grinder could likely fix this issue.

Another option is to use the alternator bracket that came with the

dorman intake manifold kit. It's got more space open towards the back

where the alternator output post is located.

The oem ford 6G alternator bracket next to the aftermarket dorman

universal

3G/4G/6G bracket

This is a universal bracket for cars with 3G, 4G and 6G alternators.

The 3g tab on the bracket comes a little close to the alternator,

cutting this unused tab off would open up some space near the regulator.

Now lets remove the alternator output wire and enlarge the ring

terminal with a 5/16" drill bit so that it will fit over the new

alternator

output stud. The old alternator uses a M6x1.0 stud on the output post,

the "new"

alternator uses a M8x1.25 stud instead.

Before modification

After modification

Now that the charging wire hole has been opened up, we can connect the

alternator output wire and begin tinkering with the control aspects of

the new alternator regulator.

This alternator will self excite without any regulator wires connected

at all, but charging voltage will only be 13.6 volts under minimal load

which is too low for good battery recharge characteristics. So we need

to find some way to raise the voltage output of the alternator. My

first idea was to use the alternators no-pcm-communication failsafe

voltage setpoint and insert a diode or two inline

with the voltage

sense

terminal to make the alternator think that the battery voltage was

lower than it actually was.

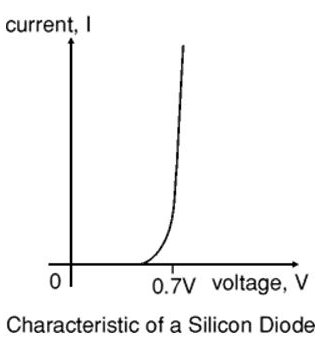

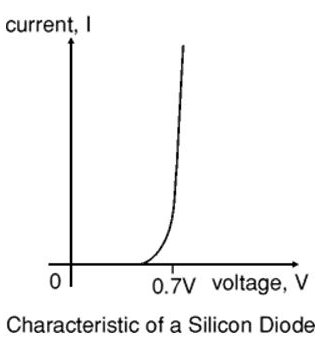

In introductory electrical theory textbooks, you'll read that a

diode always drops 0.7 volts across it. But in the real world, the

voltage drop across a diode varies as a function of current and various

other parameters. This causes the alternator output voltage to float

around some as the car runs and things heat up. At first, i was only

getting around a 0.4V drop across each diode, but later this started to

ramp up close to 0.7V across each.

Maybe some high current diodes like those in a marine battery isolator could have

solved the voltage float problem mentioned above or maybe a voltage

divider consisting of a couple resistors could have been installed

instead. But a cleaner

solution is to send the alternator fake voltage setpoint data on the

gencom line. This way, the alternator will think that it's installed in

an actual car recieving voltage setpoint requests from the powertrain

control module (PCM).

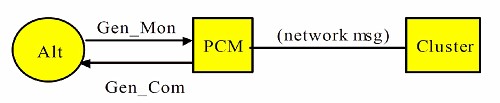

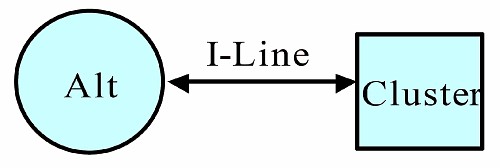

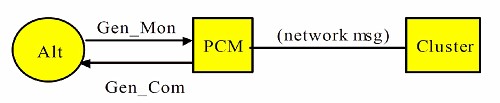

The 2003 and later crownvic alternators have a PCM controlled

alternator regulator. There are two unidirectional control lines going

to the regulator. The gencom line has information on it about what

voltage the alternator should output. And the genmon line has

information about what load the alternator is under, any problems the

alternator may have, and various other operational data.

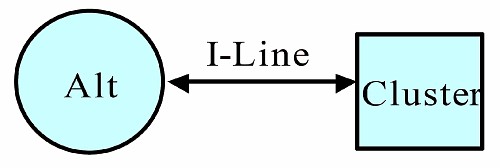

Unfortunetly, the 2002 and earlier crownvics control their alternators

differently. The voltage setpoint inside the regulator is fixed and

non-adjustable. And rotor field coil excitation voltage is obtained

through the instrument cluster i-line to tell the alternator when to

turn on/off the rotor magnetic field.

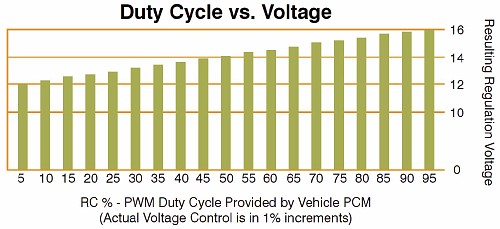

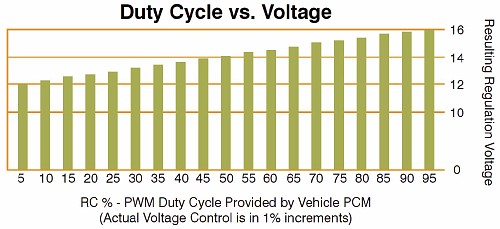

But if we place a 125Hz pulse width

modulated (PWM) square-wave signal on the alternator gencom line of

our "new" alternator, we can vary

the alternator voltage setpoint by changing the duty cycle of the

waveform.

A search for pwm circuit ideas revealed that there are a number of

premade pwm circuits on the market catering to the HHO hydrogen generation crowd. The

idea is that you can extract hydrogen from water which can then be fed

through an automobile's engine air intake system to increase fuel

economy. Many of these circuits were originally intended to control the

speed of electric motors, but we can retask them for our alternator

control project if they have an output frequency close to 125 Hertz and

they are designed to control motor speed through the ground side of the

circuit.

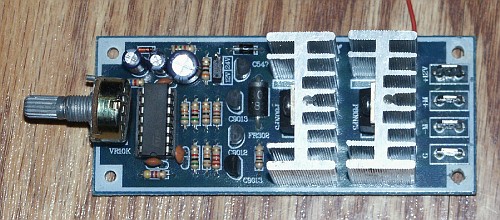

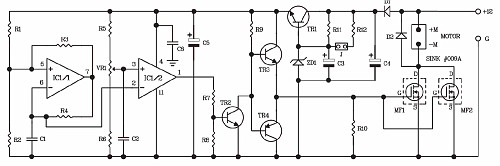

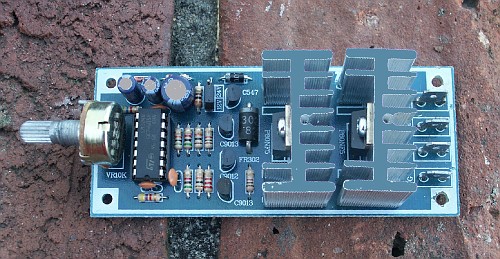

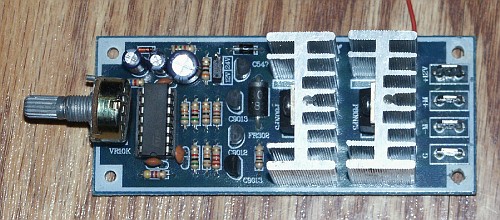

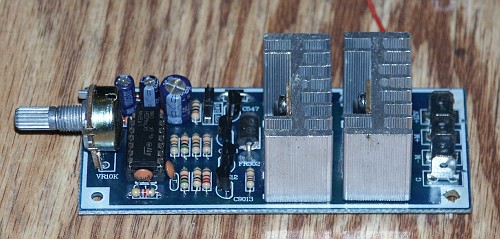

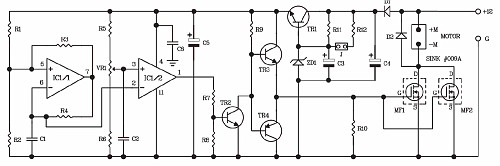

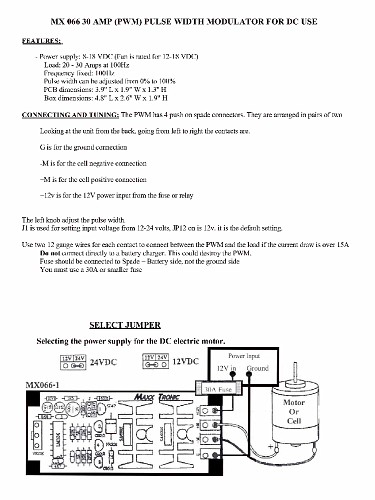

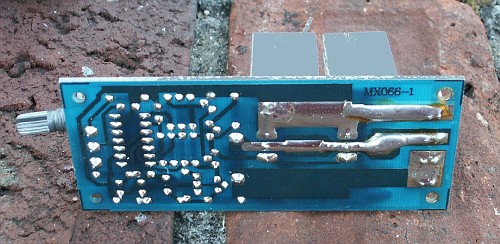

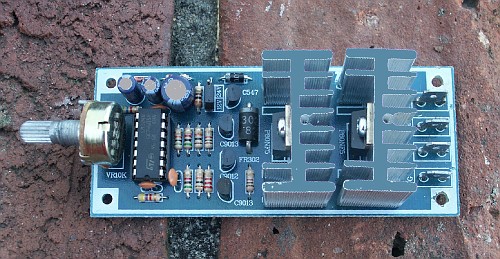

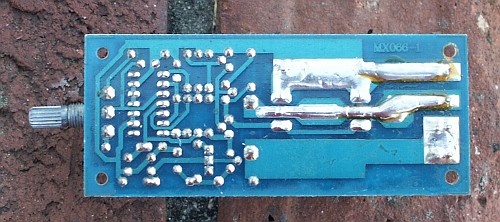

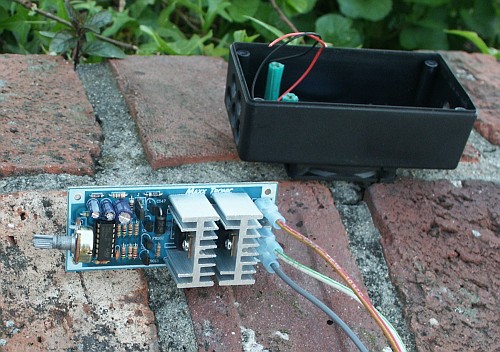

After looking at a few different circuits, i settled on the MX066 from

bakatronics.

This circuit is based on the LM324 operational

amplifier (opamp) and is

designed to handle up to 30amps which is more than adequate for our

alternator voltage regulator control application. The 100Hz frequency

of this unit is

somewhat close to 125Hz that ford generates inside the pcm to control

the alternator. But if we want to raise the frequency of the pwm to

125Hz, we will need to lower the resistance of R4 in the circuit.

This circuit turned out to work very nicely to control the alternator

even though the frequency of the pwm waveform is 25 Hertz slower then

the ford gencom specifications in it's unmodified form.

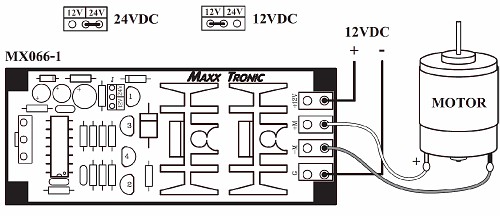

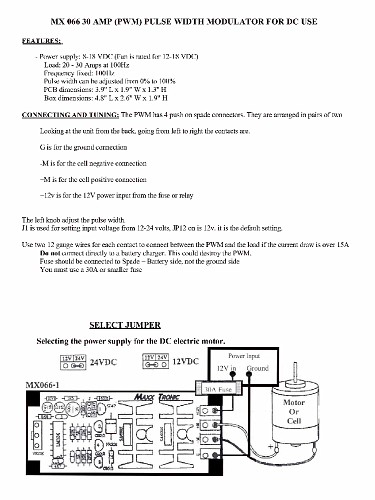

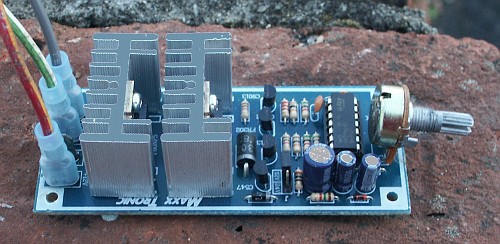

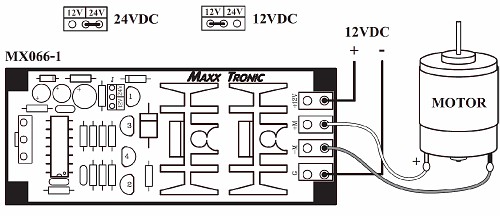

For our project, we want to crimp three 1/4" spade terminals onto 3

peices of wire and insert them onto these tabs. We will be using the G,

-M, and +12V terminals. The +M terminal will be unused since it jumps

directly to the +12V feed and our alternator already has an internal

source for +12V.

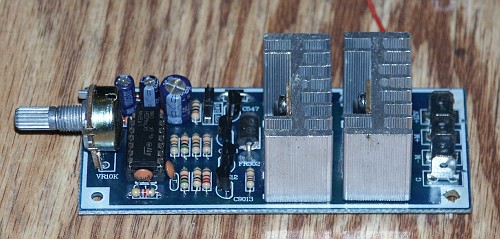

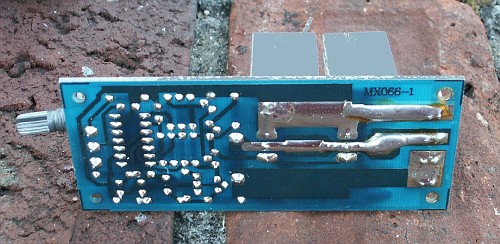

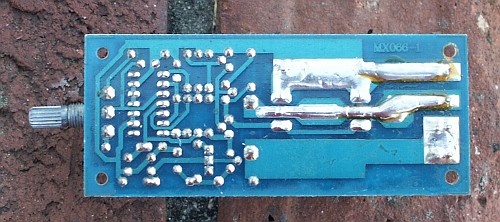

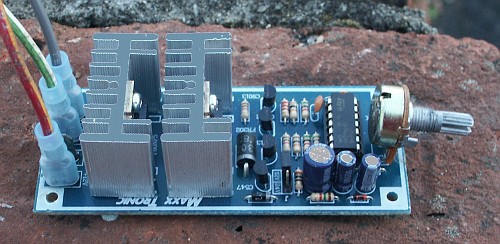

After crimping the wires and sliding them onto the circuit board

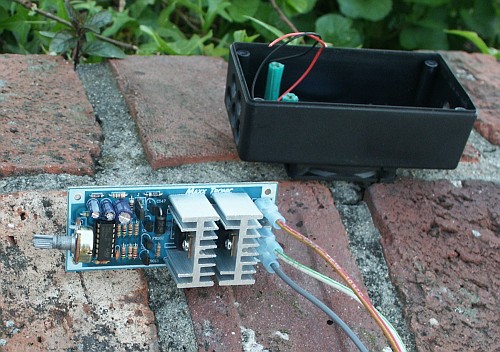

After inserting the circuit board into a case so that the traces don't

accidentally short out against metal objects

The red wire is +12V, the grey wire is ground, and the white wire is

the pwm output to feed the alternator gencom line.

Here's our testbed vehicle with the 2009 alternator installed. A new

voltage regulator wiring pigtail was purchased, and one wire of the new

pigtail inserted into the appropriate pin of the old regulator

connector to read battery voltage. The middle gencom wire is connected

to the output of the pwm device. Turn the pwm control knob

counter-clockwise and we can raise the voltage setpoint

of the alternator regulator close to 15Volts. Spin it clockwise and the

setpoint will dip down below 12Volts at the other end of it's travel

limit. The alternator voltage setpoint is very stable with batery

voltage only varying +/- 0.01 Volts given a constant load on the car's

electrical system.

Good battery recharge characteristics are obtained somewhere between

14.0 Volts and 14.5 Volts at a reasonable ambient temperature. The

regulator in the factory installed 1998

crownvic alternator had a fixed setpoint of 14.4 volts according to

transpo, but battery

voltage was actually 14.1Volts at idle with the engine running and all

accessories turned off according to my voltmeter.

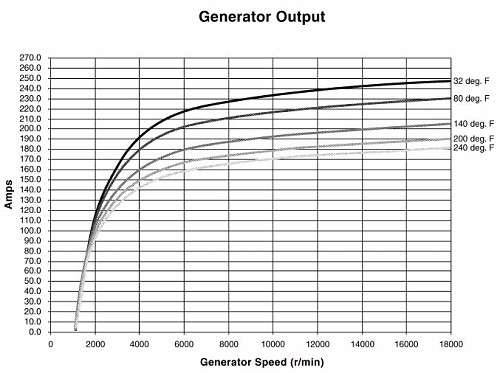

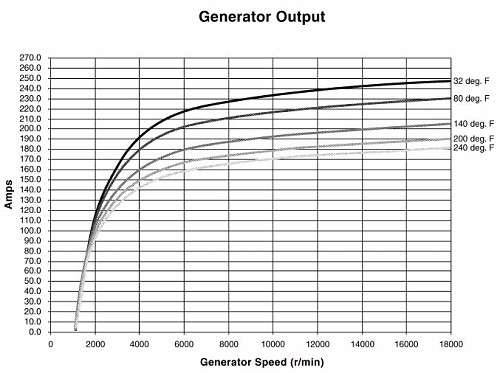

This is a really powerful alternator that ford under-rates. If you spin

the alternator really fast and the ambient temperature is low, you can

get well over 200 amps out of this unit.

Here is a reference picture of a wrecked 2005 crown victoria engine

with the alternator and it's wiring attached

(picture courtesy of

Steve83 on www.crownvic.net)

Misc Notes:

- Upgrading a 2003-2010 crownvic to this alternator would have been

considerably easier since the powertrain control module (pcm) in these

cars already generates a pwm signal on the gencom line. The pcm in the

1992-2002 crownvics does not communicate with the alternator at all

other than the fact that it uses battery voltage for power.

- A little lesson about the basics of an alternator: To get power

out of

an alternator, you first need to send power from your car's battery

into the alternator to energize the rotor field windings. The rotor is

basically a big elecro-magnet that creates a big magnetic field when

electricity is applied to it. when the car is turned off, there is no

power going to the rotor windings. In the pre-2003 crownvics, when you

turn the ignition key on, battery voltage is applied to the rotor

windings by applying +12V to the charge indicator lightbulb on your

instrument panel, power then flows through the ~6 ohm bulb filaments to

the regulator which then sends power to the rotor field windings to

create a magnetic field. Once the engine starts spinning reasonably

fast, the alternator begins to produce electricity in the stator coils

which then turns off

the charge indicator bulb by applying +12V to the bulb feed wire at the

regulator. If both sides of a lightbulb are at +12V, the potential

difference between the two sides is 0V and the lightbulb will not be

lit.

- There are two different ways for an alternator to self excite.

Rotors usually have a small amount of residual magnetism in them and

when you spin them really fast, it's sometimes enough to get sufficent

magnetism induced into the stator windings to get the electricity out

of the windings so that a full strength magnetic field can be built up

and the alternator can output at full capacity. The disadvantage of

this setup is that you often need to rev up the engine to get the

alternator to self excite. But the alternator pulley is overdriven at

about a 3:1 ratio by the crankshaft, and police interceptors have an

initial cold idle speed of close to 1000RPM so the alternator shaft

would be spinning at 3000RPM. The other method of getting the rotor

magnetic field to turn on initially is to monitor battery voltage. A

big drop in battery voltage indicates the starter motor was cranking

the engine, and the rotor field coil can be turned on by the regulator

for a couple seconds.

- Instead of generating a fake gencom signal to simulate the pcm or

sending an altered signal to the voltage sense terminal of the

alternator regulator, you could in theory get one of these alternators

working in an earlier car by hacking up the internal voltage regulator

to pass the field coil signal to an external conventional i-line

regulator. Many 1970's ford vehicles used such a voltage regulator

setup, but you must be careful to make sure that your regulator can

handle the load of such a large rotor field coil. Also, be aware that

recent internally regulated ford alternators are a-circuit with rotor

field current controlled through the ground side of the circuit. And

most external ford regulators are b-circuit regulators with field

current controlled through the positive side of the rotor field circuit.

- The Alternator Regulator Pulls:

Voltage sense low (ground) (pin 1)

Genmon low (ground) (pin 3)

Gencom high (+12V) (pin 2)

- This 2009 police interceptor alternator would self excite without

any regulator wires connected.

- Without the remote voltage sense pin connected, the alternator

was in "machine sense" mode which sensed the voltage at the output post

and commanded output 0.2V higher than in remote sense mode.

- Conncting gencom to ground caused the alternator to stop charging

or set the voltage setpoint really low

- With no gencom pwm signal fed to the alternator, the genmon line

would stay at 0V for a while, and then start sending a +12V squarewave

signal to the gencom line, and then go back to 0V for a while and

repeat the process. Connecting the charge light bulb on my 1998

crownvic's dashboard to this wire would not illuminate the light

because this is a low current feed line not intended to drive a high

current light bulb.

- The alternator genmon line has a duty cycle of a little under 50%

under minimal loading. And the duty cycle will increase as alternator

load increases.

- The 6G alternator regulator connector used in 1998-2002 crownvics

does not have a wire in the middle pin of the connector. And the

connector shell is not designed to allow installation of a new pin in

this location either. To be able to send gencom data on pin 2, you will

need to replace this connector with a new WPT-118 service pigtail from

ford or one sourced from a wrecked 2003+ police interceptor donor car.

- It can be rather frustrating on a high mileage 2003+ crownvic

when the gencom or genmon wiring gets damaged and signals from other

circuits get into these wires. Drive over a bumpy road and you might

see your alternator charge at over 16 volts for a bit, then a while

later drop so low that the car stalls out because the powertrain

control module doesn't operate properly at voltages that low. If you

suspect problems on this circuit, run a couple new wires from the pcm

to the alternator regulator pigtail for the gencom/genmon signals.

These are just signal wires that don't carry any real amperage, and

16AWG or 18AWG should be good.

- Be careful not to leave the ignition "on" without the engine

running when the using a pwm device to control the alternator. The pwm

module will command the alternator rotor field coil to engage even

though the engine isn't running. This will cause the field coil to

generate a magnetic field and build up some heat too. When the engine

is running, the alternator cooling fans are spinning to move air across

the alternator components. When the engine is stopped, the cooling fans

are also stopped, and the heat can really build up. You shouldn't have

problems with this issue if you educate the drivers of your car not to

leave the ignition on without the engine running. If you have your pwm

device wired properly, turning the ignition key backwards to the

accessory position to listen to the radio is fine, it's just leaving

the ignition key in the run position without the engine running

that is bad. If you are really adventorous, it's possible to wire the

pwm circuit to monitor the engine oil pressure or fuel injector pulse

rate to shutoff the field coil when the engine is not running.

- The MaxxTronics pwm running with no load draws about 3 amps

- The pwm components were cool to the touch after driving the

alternator gencom lead for over an hour (even with pwm cooling fan

disconnected). This is to be expected when one is running a circuit

designed for thirty amps with only a few milliamps actually flowing

though it.

- The 200amp Mitsubishi alternator used in the 2004+ police

interceptors costs about $500 from your local ford dealership. The ford

3G, 4G, and 6G alternator are about half that price.

- The alternator pulley clutch in the 2004+ police interceptors

often wears out before the remainder of the alternator components have

failed. An alternator cannot charge if it's rotor is not spinning

because of a defective clutch. Early warning signs of impending

alternator clutch bearing failure include objectionable noises when the

transmission shifts during hard acceleration or objectionable noises

for a short period of time after you shut off your engine. The noises

after you shut off the engine are because the alternator rotor has a

decent amount of mass and continues to rotate, but the engine accessory

belt holds the alternator pulley stationary causing the clutch to

overrun.

- The mxa066 pwm has linear control over the regulator voltage

setpoint. At one end of the spectrum, the alternator charging output is

effectively shut off because the voltage setpoint is so low. At the

other end of the spectrum, the alternator output will climb close to 15

Volts. But there is an odd spot in rotating the knob after the voltage

peaks at 15Volts. After that point, the voltage abruptly drops to

13.2Volts and stays there for the remainder of the rotation range

instead of climbing higher. It is suspected that this is because the

pwm is outputting 100Hz instead of the 125Hz that the alternator is

designed to accept, and the alternator regulator goes to a failsafe

setpoint at this point.

- After installing the 200amp police interceptor alternator, you

will want to upgrade the 6AWG charging wire and the fuselinks which

protect

the charging wire from overload. The factory installed 4G and 6G

alternators use (one single 8AWG fuselink) or (two 12AWG fuselinks in

parallel) for circuit protection.

The police interceptor alternator uses two 10AWG fusible links in

parallel, but a 300amp aftermarket ANL car audio fuse should work

instead. Fusible link wires are basically very slow blow fuses

constructed of specially designed undersized wire with extra thick

insulation that can

withstand very high temperatures. Do note that current flows in a loop

and you need good ground wires too, but the factory installed ground

wire is already rather thick because it carries the full load of the

engine starter motor.

- The output battery post stud on the 200amp mitsuibishi alternator

is M8x1.25 which will have a diameter of approximately 8mm. To

construct a custom charging wire, ideally you would use a metric #8

ring terminal lug on the alternator end. But, these are not readily

avaliable and you will likely end up using an SAE 5/16" ring terminal

lug from an aftermarket autoparts store, car audio shop, or marine

boating supply store instead. 5/16

inches = 0.3125 inches = 7.9375 millimeters. Do not purchase an SAE

3/8" ring terminal lug because this is too large, 3/8 inches = 0.375

inches = 9.525 millimeters.

- If you downgrade back to a ford 6G alternator, the output

charging post stud is M6x1.0 which will have a diameter of

approximately 6mm. To construct a custom charging wire, ideally you

would use a metric #6 ring terminal lug on the alternator end. But,

these are not readily avaliable and you will likely end up using a SAE

1/4" ring terminal from your local autoparts store, car audio shop, or

marine boating supply store instead. 1/4 inches = 0.250 inches =

6.350

millimeters. If the mitsubishi alternator that you acquire has been

rebuilt before, there is also a possibility that the alternator

charging post will have an M6 stud instead of an M8 stud on it too.

- The battery cable post that the alternator charge wire connects

to on the underhood fuseblock of 1992-2002 crownvics is an M8x1.25

stud. Do note that the factory installed nut on this stud is odd in the

sense that it limits travel of the nut on the stud. So you can install

the M8x1.25 nut from a mitsubishi alternator onto this stud. But you

cannot install the fuseblock nut onto a mitsubishi alternator because

the indented area of the nut will grab against the alternator charging

post stud threads before it can be tightened down enough to properly

hold the charging wire in place.

- The oem ford alternator output wire ring terminal lugs have a

grey colored tin plating on them to protect against corrosion. The

actual terminal underneath the coating is made of a copper alloy. In

the aftermarket, ring terminal lugs are avaliable with and without the

tin coating. And ring terminal lugs are usually located in the car

battery or engine starter motor section of retail automotive parts

stores. In the aftermarket car audio world, many ring terminal lugs

come with gold plating appled to protect against corrosion. Gold and

tin are both effective at preventing corrosion of the underlying metal,

but some people prefer the cosmetic appearance of gold colored

electrical components over the dull grey color of the tin plated ones.

- It is also worth mentioning that a tutorial on

crimping battery cable ends is avaliable here.

- Some pictures of the fusible links that are located between the

alternator output wire and the vehicle's battery on the 1998-2002

crownvics are avaliable on the

battery

cable

harness

webpage. Do note that the 1998-2002 crownvics

are somewhat odd in the sense that the alternator fuselinks are not

located in the charging wire that connects the alternator charging post

to the underhood fuseblock, but rather in the wire that connects the

fuseblock to the battery. In the 1992-1997 crownvics, the alternator

fusible links are located in the charging wire which connects the

alternator output post and the underhood fuseblock.

- A technical service bulletin about retrofitting the 200amp

mitsubishi high

output alternator into a 2003 crown victoria is avaliable by clicking here. A special service message

(ssm) from the ford oasis network about the powertrain control module

calibration referenced in the previous tsb is avaliable by clicking here.

- Some people may wonder whether it is possible to create their own

kit to make installing a 2004+ police interceptor alternator into their

civilian crownvic plug and play. This is possible, but it's also rather

expensive. First, you need to acquire a 2004+ crown victoria police

interceptor alternator, then you need to order the appropriate model

year police

interceptor battery cable harness (the alternator charging wire is

part of the battery cable harness in 03+ crownvics). And finally, you

need to order the little jumper cable extension harness which connects

the alternator regulator to the connector on the car's electrical

harness (part # 3W7Z-14A411-DA). Do note that you cannot use the

3W7Z-14A411-DA jumper harness on a 2003-2004 civilian crownvic, and

would need to replace the entire fuel/charging electrical harness. But

you might find it more cost effective to just cut-n-splice on a

1U2Z-14S411-TA (WPT-118) regulator pigtail onto your existing

fuel/charging harness, and custom fabricate something for the high

current alternator output wire instead.

- There is programming information inside the powertrain control

module specific to the alternator model that a crownvic originally had.

But some people have upgraded their 2003+ civilian crownvics from the

4G civilian alternators to the high output police interceptor

alternators by just splicing on a different alternator regulator

pigtail and upgrading the output wire. And some police interceptors

have had their 200amp mitsubishi alternators downgraded to the 135amp

6G alternators by just plugging in the new alternator. In both cases,

no driveability problems were reported despite not reprogamming the pcm.

- There has been some debate about whether the small electrical

extension harness extension is really needed to install a 2004+

alternator into an earlier vehicle that's wired for the ford 6G

alternator. Both alternators use the same electrical plug for the

regulator, but the cars with the mitsubishi alternator have a longer

regulator connector takeout than the cars with the factory installed 6G

alternator do. Some people have said that they were able to stretch

their fuel/charging wiring harness to reach the alternator regulator in

its new location by disconnecting some harness->engine retainers and

giving the harness a couple sharp pulls, but this is asking for

trouble. Attempting to elongate an electrical harness by stretching the

wires inside is going to damage the harness and could cause you

nightmare electrical problems in the future.

- There has also been some debate about whether the external

control box for the alternator regulator is really needed when

installing a 2003+ alternator into an earlier car. Some people are

adamant they installed pcm controlled 2003+ alternator into an earlier

car and it worked great without the external pwm box. While many 03+

alternator models will self excite and start charging if you install

them in an earlier crownvic, they will only charge at a little over

13Volts. This is too low a voltage for good battery charging

characteristics. The alternator might seem to work acceptably for a

brief period during

the warm summer months in a hot southern enviroment like florida. But

you're going to have problems starting your car's engine during the

winter months if you live in a cold enviroment like northern new

england or canada. Good battery recharge characteristics are obtained

somewhere between 14.0Volts and 14.5Volts. You can safely raise the

charging voltage a little beyond that on really cold winter days too.

- On internet discussion forums, you'll often see www.custombatterycables.com

recommended for supplies to make custom automotive battery cables.

There are also

a handful of vendors location on www.ebay.com

that sell similar supplies. Many people have also ordered automotive

battery cable supplies from www.genuinedealz.com.

This

place

caters

mainly to the marine boating crowd, but their cable

supplies work very nicely in an automotive enviroment too. Having

battery cables that are really resistant to water and salt corrosion is

a very good thing during the winter time in the northeastern united

states. The local highway departments in this area of the country apply

tons of chloride salts to the roads to melt snow/ice during the winter,

and the engine bay of a car driven on northeastern highways during the

winter will often look like a it has been operated in salt water marine

enviroment.

- TheShadow

on

www.crownvic.net commented "Does the Mitsubishi

allow for a larger overall diameter ring to be used? I'd be a little

leary about using an existing 135-amp circuit ring terminal and

boosting the current through it so much, and having to decrease its

cross-section at the same time. Possible work-arounds might be just

adding a washer to match the extra size (if any), or using a thicker

ring terminal." This is a very valid point. And in my case, the

alternator was just connected for temporary testing purposes this way

while I let the car idle in the driveway for a few hours with the hood

open. Something else is going to be custom fabricated when the

mitsubishi alternator upgrade becomes a permanent installation.

- Wiring diagrams for ford crown victorias and

mercury grand marquises are avaliable if you click here.

- For possible mounting locations for the pwm: you could mount the

pwm module to the driver's side of the rear seat strainer in the trunk,

this is where the factory keyless entry module used to be mounted in

the 1992-1994 crownvic lx's. On the 1998-2002 crownvics, there is also

an unused location down low in the passenger's side a-pillar near the

door hinges where the airbag crash module used to be located in the

1992-1997 crownvics. The technicians at your local car alarm and remote

start installation shop can likely think of other mounting locations

for you too, but you must not mount the pwm under the hood because this

area has lots of water passing through and electronics are easily

damaged by water.