the condensor in the 1998 crown vic uses "peanut" block fitting connections.

| vic1992LX: very useful,what about the compressor and other components? |

| lots of

pictures of the old compressor with it's burned up clutch avaliable if

you click the link below: http://www.p71interceptor.com/accompressor/disassembled  |

| it should be

noted that the vehicle in question has a new radiator/ac

condensor fan assembly installed. shortly before the old compressor

burned up the clutch, the old fan assembly failed and didn't move any

air across the condensor anymore. having really high head pressures

might have

contributed to the early demise of the compressor clutch. in civilian vehicles, the electric radiator fan often lasts the life of the vehicle. but, a marked police cruiser with engine idling for hours at a time = really high duty cycle for fan = accelerated wear rate for fan motor brushes & bearings. |

| LTDteether: Is this the first time you've replaced any o-rings? I had leaks in some of my connections years ago. |

| yes, the a/c

system o-rings were still the original ones installed 10+ years ago by

ford. the refrigerant leak started off slow, and for the past couple years i'd have to add a 12oz can of refrigerant to the system every summer. recently, the system started to leak much faster and then the a/c compressor clutch burned up too. |

| Fordiesel69: Two points worth mentioning. The compressor is prefilled with oil. This is bad. PAG and POE oils are extremely hygroscopic. When satuarated with atmospheric water molecules, it will become an acid as well as a lubricant. This will eat the condensor and evap over a period of time. Best thing to do is dump the factory fill oil out of the used compressor or new compressor and install fresh out of the can (sealed) genuine ford oil, and get the compressor installed in 15 minutes and sealed and in a vacuum or top with nitrogen until you can get it to a shop to do the vacuum. The compressor is the LAST part to be installed. After about 15 minutes the oil becomes saturated and the silicate in the drier will not be able to remove it. The other point would be, to never let the car "sit" in a vacuum. This old rule has been superceded in the HVAC industry now being new oils are introduced. Back in the mineral oil days this was fine. Ideally, you want to get the vacuum to -30 and then down to 400 microns using a micron guage. You could even settle for 700 for automotive systems. But without a micron guage, its just a guess. You also should never remove your guages, and then put a can tap on. This alone will break the vacuum considerably. Sorry for going against what you did, but you did break your vacuum and performance + longjevity will be reduced. Other than those two points, excellent writup. It sure beats paying a shop $300+ labor to do all this. |

| Chevyguy: 400 - 700 microns is a pretty low vacuum level. My big old pump at work can get about that low on one of my flask setups. I use a mm HG or Torr gauge and getting below 1 mm (1000 microns) takes work. |

| Steve83: Last I checked, Ford still

recommended reusing the drier by 1) warming up the engine (so the drier

would stay warm) & then 2) applying vacuum for 30min-2hr to boil

out any moisture. And I doubt the oil will become "saturated" with water in a few minutes, or ever with the factory shipping plugs in the compressor ports. If it was THAT easy for humidity to get in, the oil would pour out during handling. And water just doesn't mix with oil that easily. It happens inside a working A/C system because of the pressures, temperatures, and the homogenizing effect of the orifice tube. But just pouring the oil from the can to the compressor, there's not enough surface area or water for it to mix THAT fast. |

| i took a break

in the middle of the a/c repair project and left the a/c system sitting

in vacuum without any guages connected overnight. seemed like a better

choice than letting the system sit full of ambient air overnight. then i connected the guages in the morning and found the system was still under a good vacuum. but reconnected the vacuum pump and let it run for a little bit anyways. for refrigerant filling, i used a can tap with a really short hose connected directly to the low pressure suction port on the accumulator. probably introduced some ambient air into the system that way, but not terribly much. |

| it should be

noted that the pag oil used in our a/c compressors has a really high

surface tension. you can indeed get some oil out by rotating the

compressor input shaft with the refrigerant ports open. but the oil is "gooey". as a result, a decent amount of oil inside the compressor will stick to the metal parts and won't come out without complete compressor disassembly.  |

| i ordered a

new visteon compressor for this project. it came with a plastic plate

placed over the suction/discharge ports on the compressor. the ports were well sealed as no oil leaked out of the compressor during shipment. it was also very difficult to rotate the compressor input shaft using the front clutch hub when it arrived. but after removing the plate from the ports, the compressor rotated very easily using my fingers to turn the front input shaft hub. |

| LTDteether:

Let's apply

some logic here. First, you can't really set a simple cut-off point for

how long the oil-charged compressor or system is open. Every moment

they are open, moisture gets in. Think of the amount of moisture in the

system as a rising curve on a graph. You want to have it closed as much

as practically possible. The Ford advice to warm up the engine is

interesting and probably a good idea, but I wonder if they have any

data to back it up as beneficial. If the lubricant is hygroscopic and sensitive to water-induced breakdown it becomes even more important to keep moisture out. Of course you can't be perfect which is why you have the dryer. What I am gleaning from the above information is that the water in the oil reacts with the oil so you have two processes occurring, absorption and that chemical reaction producing acids. I don't know the half-time for either, but if the second is significnantly longer than the first, the dryer is there to take car of it. That is probably really what it is there for rather than for any continuing contamination of a pressurized system. Yes, Ford recommends reusing the dryer and I would not fault anyone for doing that. It might be advisable to get a new one if you are not working under ideal conditions. That means if you have a sub-par vacuum pump and are in a humid environment, or have to plug up your system and drive to a shop to evacuate and fill. Getting away from logic, I understand that drying stuff under vacuum is a pretty inefficient process compared to using a chemical drying process (like silica gel or calcium carbonate). At least that is what I learned from electron microscopists about drying their film. They could have been full of ca ca, though. In any case don't see how a prolonged vacuum would hurt, it may be that the small gain is not worth the expense if you are doing it in a shop. It might remove moisture from the oil in the system. This is a great thread |

| as the a/c

system is vacuumed, the boiling point of water goes down. warming the

engine bay also helps get the water to a boil with less vacuum. you can also observe water boiling point alteration with the pressure cooker that your grandmother used to have in her kitchen. raise the pressure inside the cooking pot with a tight lid, and the food cooks faster because the boiling point of water is raised.  |

| let the car

idle today for a while in the driveway on an 80+ degree day. then used

an infared thermometer to probe the temperature at various points

around the car. results in fahrenheit: -dashboard vent discharge 35 degrees -seat surfaces 48 degrees -exhaust manifolds 478 degrees -high side pressure hose assembly near service port 122 degrees -tailpipe output under rear bumper 108 degrees |

| kustomizingkid: Awesome write up! |

| Some people

have reported leaky valve cores on their service ports. |

| But

in my case, a new low side schrader service port valve core came with

the accumulator. The high side schrader valve core on the discharge

hose seemed to be holding pressure acceptably, so it was left in place.

Note that the refrigerant valve cores come in different diameters and different thread pitches, so make sure to get the right ones for your particular car. A bicycle tire valve core tool can often be used to remove the a/c system schrader valves, but there are ones specifically designed for a/c applications which have a longer shaft length for getting out a/c valve cores mounted deep inside the service ports. Some people have reported sucessfully removing the a/c valve cores using a fine tip pair of needle nose pliers, but this method is not recommended. |

| tackleberry: some parts store clown mentioned putting a little bit of propane in the ac system. i was like ?????? |

| Propane will

work as a refrigerant. It's called R290. used to see some backyard mechanics fill their a/c systems with propane when R12 got to $50/pound and you started needing a permit to purchase it. it's rare to see propane used as a refrigerant in cars these days because all vehicles manufactured in the past 15 years have R134a for factory fill. and this stuff is only $10/pound and no permit is required to purchase it in most parts of the country. p.s. here's a link to the MSDS for propane r290 |

| LTDteether: I would not be surprised if propane improved

the operation of the system considerably. I would not be surprised if

it made it worse or killed it eventually. There are plenty of

refrigerations systems that use some propane in the mix. I believe it

is getting less common. I would not try it unless I had some

information from an engineer familiar with these systems. There are

just too many things to consider. Just for a simple example, the

o-rings might be soluble in propane; how's that going to work for you?

What about the compatibility with the oil, compressor seals,..... How

'bout the boiling point of the mixture? Blast you, 2V, beat while composing again. Now that I think about it, I had a bottle of propane refrigerant in my hands once. It was an identical bottle to the small (1#?) propane bottles you would screw onto a torch as far as I could tell. The material inside is a lot more pure. Rather than waste it for fuel, I gave it to the company that repairs our lab equipment. I don't think my pipes could tell the difference. |

| tackleberry: supposedly its supposed to make it colder tan 134a when mixed. |

| the a/c system

in these cars has a great deal of extra capacity for those people

living in the northeast united states. i can easily ice over the

evaporator core by jumping the low pressure cycling switch on my

crownvic. |

| mrbear3800: It would suck if there was a pinhole leak in the evap core and you went to light a smoke... |

| http://www.arap.org/adlittle/5.html |

| vic1992LX: when i turn A/C on after sitting one night, the

compressor works for 4 seconds then it shut off for 4 seconds, this

still happening for 5 minutes after driving then it still working. idk maybe there is leak or clogged filter/drier? |

| during a/c

service, the accumulator is usually replaced with a new service

assembly. this prevents any debris from inside the old accumulator from

re-entering the refrigerant system and also will install a new

accumulator desiccant bag to absorb moisture. some pictures of the

internal parts from crown victoria accumulators are avaliable by clicking here. while the system system is open, also inspect the orifice tube for any debris that may be lodged on the filter screen.  |

| vic1992LX: how much gas pressure should be to say that the compressor is in a good or bad state? |

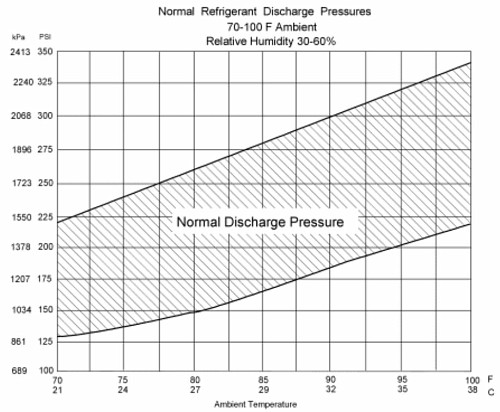

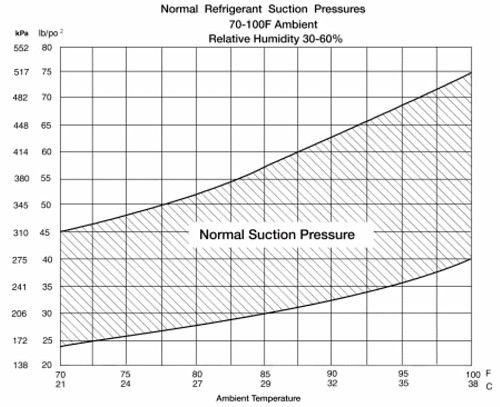

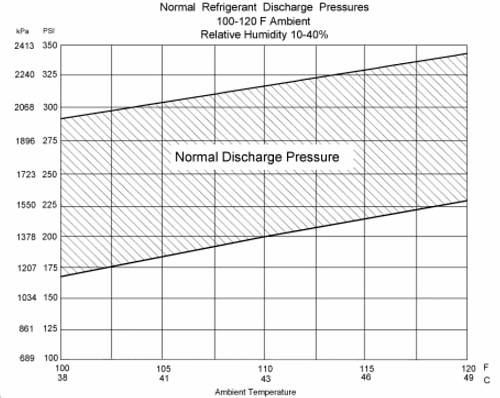

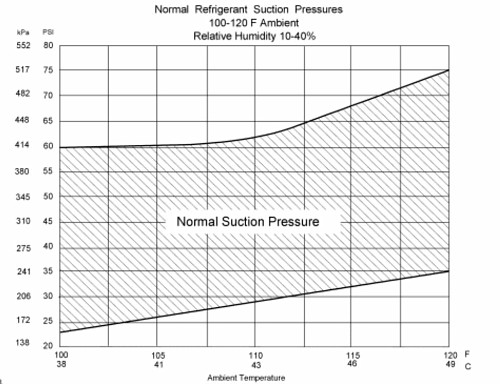

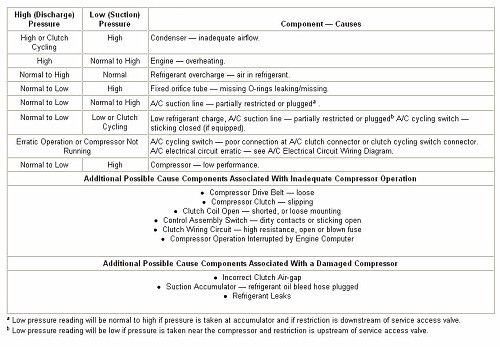

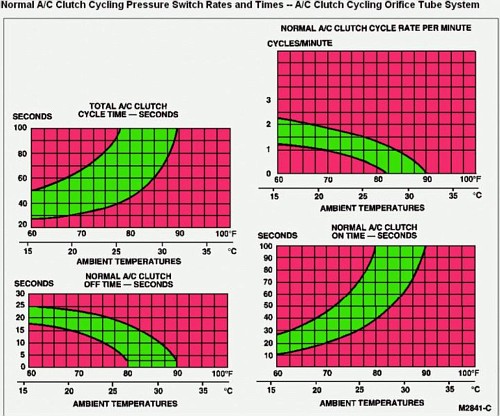

| here's an excerpt from the

service manual. ideally, you'd have a refrigerant machine to recover the refrigerant charge from the system and weigh it. but the crownvic uses a fixed displacement a/c compressor (not a variable displacement unit like found on some other cars). so the temperature/pressure graphs should work reasonably well.      |

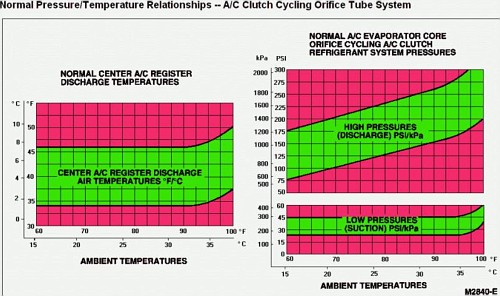

here are a

couple more a/c charts   (coloration added to pictures by no0c on lincolnsonline) |

| CV94: My 1994 Mercury Grand Marquis started blowing hot a/c air this season. The compressor clutch just cycles on and off at idle. The low side gradually in about five seconds increases from l5 to 45 and then the compressor comes on and pumps it back down in about 2 seconds. Then it immediately does this over and over. From Ford disgnostics this appears to be a restricted orfice tube or a/c liquid line. Auto Zone sells the tube for $5 and another for $25. They say all I need is needle nose pliers to pull the tube out where Ford has a special tool. Did you just use pliers. Do you know if I can use the $5 tube instead of the $25. Harbor Freight Tools has the manifold for about $50 and a vacuum pump of 2 and one half cfm for about $80.So I can replace the tube for about what some want just to check out system.Do you believe this would work? |

| the orifice

tube on these cars is in the lower liquid line of the evaporator.

often, the orifice tubes slide out easily with a pair of needle nose

pliers. the orifice tube acts like a filter for the a/c system. and if it's completly filled with debris, you'll need to install a new a/c compressor and either flush or replace all of the other a/c components to make a long lasting repair. that's why you're probably getting $1,000+ quotes to repair the clogged orifice tube issue when the orifice tube itself only costs around $5. |

| Michigansquadcar: It is not a filter. What it does is it takes liquid refrigerant and vaporizes it into a gas into the evaporator. An orifice tube is a metering device, its a cheap inexpensive system used on these cars. Chrysler uses a more expensive system that utilizes an H valve (metering device) to introduce refrigerant into the evaporator that can be more precise. |

| the orifice

tube serves two purposes: -the white mesh screen catches debris in circulation -the precision machined brass metal tube inside meters refrigerant if you were to pull apart a few low mileage 1-2 year old cars, you'd usually find some fine metal particles from the compressor on the orifice tube screen. this is normal. if the orifice tube screen has so much debris on it that refrigerant flow is completly blocked, this is a not normal and indicates some sort of component failure. |

| Some questions

have been raised about how to remove the refrigerant from a car's air

conditioning

system during service like replacing o-rings seals or a

compressor. Before the 1990's, a common practice was to put on some thick winter gloves and depress the schrader valve in one of the service ports with a long screwdriver until the hissing sound stopped and the a/c system was completely empty of refrigerant. Sometimes in a small refrigerant system with an unknown charge level, the entire system charge would be vented to the atmosphere and then a new known amount of refrigerant later installed. But starting in the late 1980's, a series of federal clean air regulations were introduced in the united states. At first, the R12 refrigerant used in car air conditioning systems was phased out because it was depleting the ozone layer. A more eco-friendly R134a refrigerant was then phased in as a replacement. In the early 1990's, legislation was introduced to prohibit the venting of R134a refrigerant to the atmosphere because this gas has a high global warming potential even though it is not harmful to the ozone layer. At this point, a number of expensive refrigerant recovery machines appeared on the market that could reclaim the refrigerant from a car air conditioning system, weigh the charge, filter the charge, and then reinstall the refrigerant back into a car after the repair work had been completed. If you live in the united states, intentionally venting refrigerant can be either a civil or a criminal offense depending on the mood of the federal justice department at the moment. This means you could get big fines or even prison time if you're caught knowingly venting large quantities of refrigerant to the atmosphere. So although venting refrigerant to the atmosphere still works good from a technical standpoint as long as you do so in a well ventilated area to avoid hypoxia, do not do it. It is bad for the enviroment, and you could get in trouble if you get caught. For the shadetree mechanic that wants to service their car's air conditioning system and needs to remove the refrigerant, here are a couple options: -In some areas, there are small family run salvage yards that have refrigerant recovery equipment on hand. Sometimes this recovery equipment is just a propane container intended for a gas barbecue grill with different fittings installed on it. Some of the wrecking yards in your area might be willing to recover your refrigerant for a minimal fee or for free. But do note that you are giving away your refrigerant and will not be able to reinstall it if you choose this option. You will need to purchase new refrigerant after your repair is completed. -Some professional repair shops might be willing to recover your refrigerant for a minimal fee or for free. But you might have to hunt around a little bit to find a cooperative shop or you might not be able to find one at all. It should be noted that if you had a very large leak in your car's air conditioning system, then you might not have any refrigerant charge left in the system at all. Something like the a spring-lock connection popping apart on a discharge hose connection due to excessive pressure is not unheard of. And collision damage car rip open a condensor allowing all the refigerant to escape in less than a second. In such cases, you do not need refrigerant recovery equipment when you service the a/c system because there is no refrigerant left inside the system to recover. The federal clean air regulations were not violated in these cases because the refrigerant discharge was not an intentional act and the refrigerant charge was not knowingly vented to the atmosphere. It should also be noted that the internet has a global reach. And if you are located in a country other than the united states, you might be able to legally vent refrigerant to the atmosphere during service. Not all countries have ratified the united states sponsored clean air treaties. But please keep the enviroment in mind and consider using the proper recovery equipment even if you are not legally required to do so. |

| The 1998 ford crown victoria

uses a variety of air conditioning refrigerant fittings. The condensor

connections are "peanut" block fittings. The evaporator->accumulator

junction is an MIO (male insert o-ring) connection. The

compressor->manifold block junction uses special fs10 specific

o-rings. The other connections are either 3/8", 1/2", 5/8" or 3/4"

spring lock connections. |

| www.acsource.com sells vehicle

specific o-ring kits to make collecting parts for your a/c system easy. "This kit contains all o-rings for this vehicles A/C system. The new revolutionary Patent Pending line of Rapid-Seal Service Kits are designed to provide a single kit to seal all of the air conditioning connections on a single car. Individual Cap and Valve kits have been included in the line as well. All kits are application specific using electronic data or printed application data. Santech has expanded it's coverage on Rapid Seal Kits to now include Acura, Audi, BMW, Honda, Infiniti, Lexus, Mazda, Mercedes, Mitsubishi, Nissan, Saturn, Toyota and Volkswagen. This puts our coverage at 96% for USA, Asian and European vehicles in the US car population 2005-1985. As with the previous domestic vehicles kits each model was researched for exact component requirements for that vehicles application. This makes the kit a tailored fit reducing cost of expensive plastic box kits and having a part number specific kit that can be applied by Make, Model and Year to a vehicle. All components are HNBR material and meets or exceeds OEM specifications." |

also, make

sure that your evaporator is clean. you can inspect it by pulling out

the blower motor.  |

| The condensor on these cars also

sometimes gets clogged up with debris too. If you remove the radiator,

you can clean off the condensor using a garden hose. Do not use too

much water pressure or you may bend the fins though. |

| There has been some talk about

the combination a/c refill cans that you can find at walmart, autozone,

etc. Most of these will have r134a refrigerant in them which is what you're after for your crownvic. However, many of these combination cans will also have leak sealer in them. This sounds good in theory because low refrigerant charge is usually the result of a leak somewhere. Unfortunetly, these leak sealers are also good at sealing things up things you don't want sealed up like the small hole in your orifice tube. The design idea of these sealers is that refigerant will leak out through external holes that shouldn't be there and then the moisture in the external ambient air will cause the sealer to harden into a superglue like substance around the unwanted hole. Unfortunetly, older a/c systems usually have some residual moisture inside them so the sealer will become active when it's not supposed to be. Even if the your a/c system is completely dry and the leak sealer does not harden up prematurely, you can still end up with a big expensive mess if you later have to discharge the a/c system and let ambient air in for some sort of component replacement service. Many of these combination cans will also have refrigerant oil inside them. You need PAG46 oil for your 1994+ crownvic's a/c system, and other oils can cause accelerated component wear. No one refrigerant oil will service all vehicles. Recent ford cars generally use PAG-46, recent BMW's are PAG 100, recent general motors vehicles are PAG-150, etc. Many of these combination cans also have some sort of PROA additive in them that is reported to boost a/c performance. The effectiveness of these additives at improving your car's a/c system performance is questionable, but these proa additives by themselves do not usually seem to cause problems. For the lowest risk of complications in the future, purchase straight r134a refrigerant without any additives. You might have to hunt around a little bit for such a product, but it's well worth the effort. |